Watch Our 1 min 40 sec Video:

Read The 8 Stages of Check Valve Operation Guide:

For over 40 years, Smart Products USA, Inc. has focused on the intricate details of how one-way check / pressure relief valves work in low pressure, low flow devices. Sharing this knowledge with existing and potential customers can save them time and money as they develop their current or future applications.

As a resource, the information below answers critical questions, such as:

- Will a certain step affect the device’s performance?

- Is there a part in the operation process that will be critical to the application?

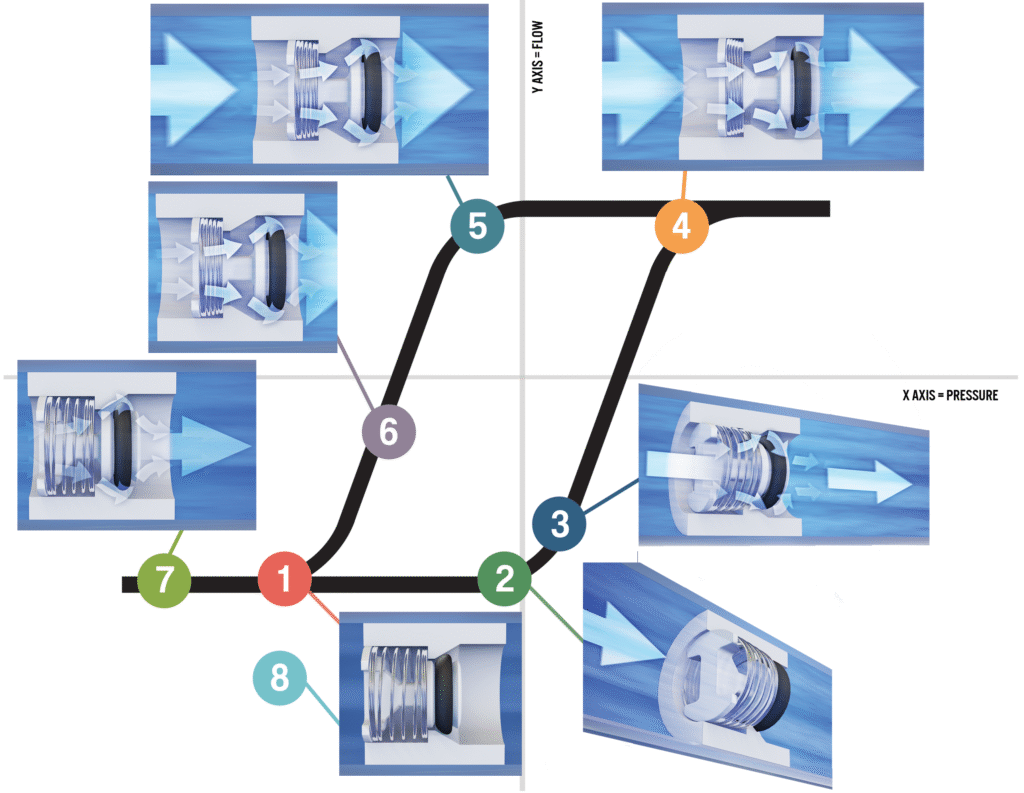

This guide describes the check valve operation process in eight stages:

Stage 1: Shut

Stage 2: Opening

Stage 3: Open

Stage 4: Fully Open

Stage 5: The Descent

Stage 6: Touch Down

Stage 7: Resealing

Stage 8: Reset

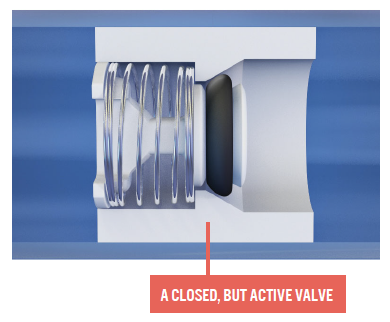

Stage 1: Shut

The Active & Passive States of a Closed Check Valve

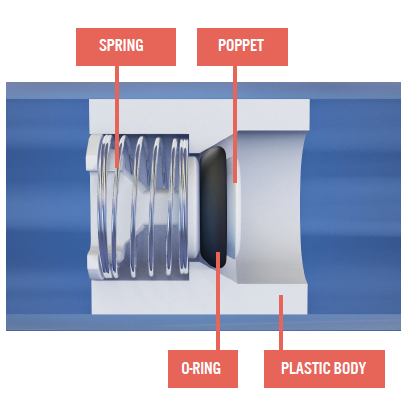

During the first stage, the valve remains shut and prohibits flow in either direction. The valve is not inactive; there is a lot of action taking place because the laws of physics continue to rule over the valve in what can be described as passive and active states.

Passive

All valves begin in a passive state. They are not yet in contact with any liquids or gasses, but the valve’s components – plastic body material, o-rings, poppet, cartridge, and springs – remain in contact with each other. The laws of physics win again if certain body materials and o-rings remain together for long periods of time, and two factors should be considered in any application: 1) leak rate and 2) stiction. Leak rate can be easily understood when looking at a bicycle tire. If the tire loses 1 PSI over one week, it has a leak rate of 1 PSI per week.

The next potential issue during the passive state is stiction. Again, if a valve is inactive and sits for a long period of time, the o-ring can stick to the o-ring seat and cause an elevated opening pressure.

Stiction can also occur if soft o-rings are used. Awareness of these two issues is the first step to ensure a valve’s optimal performance when evolving from the passive to the active state.

Active

Once the valve makes contact with a liquid/gas, it

becomes active and will never return to the passive state. While the valve is still closed, the o-rings play a key role when they first encounter the liquid/gas for the following reasons:

- Certain chemical components can make the o-ring expand

- Certain liquids, such as water, can contain debris that will not allow the o-ring to seat correctly

Application Environment

A final consideration is an application’s environment because it can also affect the passive and active states of a closed check valve.

- Will the valve reside in tubing?

- Will it be external or exposed to elements such as temperature, humidity, sunlight, etc.?

The answers to these questions could affect a valve’s performance based on the selected plastic body material and o-rings. Additionally, to ensure optimal valve performance every time, it is important to consider the following:

- Shelf life of a valve

- All liquids / gasses coming into contact with the valve

- Application environment

At Smart Products USA:

We are checking for tiny changes in pressure to assure our valves are sealing well. We test our valves for leak rate in the check direction. If the valve can hold pressure to our stringent requirements, it is accepted. To ensure maximum performance, we perform a leak test on 100% of our valves.

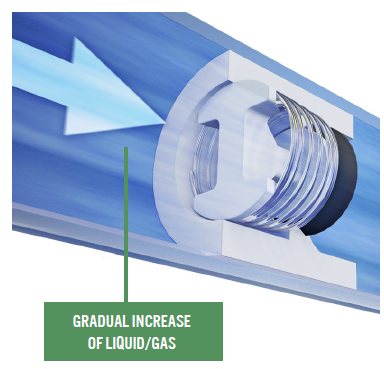

Stage 2: Opening

The “In-Between” of Shut & Open Valves

Stage 2 of check valve function is a balancing act between being shut in Stage 1 and open in Stage 3. A check valve’s nature does not allow them to be switched on and off, and this stage is notable when building a custom valve for a specific application criterion.

Once pressure has increased just enough to counter the force of the spring holding the o-ring against the seat, a small amount of flow will escape. Depending on the application, this stage can be viewed one of two ways: as an insignificant or significant amount of flow. A key question to consider at this stage:

- Will the initial opening of a valve affect my application?

The answer will help to determine which spring pressure and o-ring combination are ideal in order to control flow between Stage 2 (barely open) and Stage 3 (open).

O-rings & the Cartridge Seat

Another consideration of Stage 2 is to understand the key role of o-rings and the cartridge seat (a.k.a. poppet). To the naked eye, o-rings appear perfectly smooth. However, by nature, they often have tiny imperfections that can, over time, allow flow to escape. Once o-rings are selected, they are wedged into the cartridge seat to create a seal.

At Smart Products USA:

Our team has developed extensive knowledge about o-rings and how they perform in our valves.

This information allows us to have some control over a valve’s performance by:

- Washing o-rings twice to remove any debris

- Curing o-rings to affect their properties via various methods (i.e. sulfur, peroxide, etc.)

- Prescribing a soak test (if needed) to determine chemical compatibility

- Selecting o-ring materials and durometer (hardness of rubber), as well as spring force to be an ideal match for a specific application criterion

All of the above solutions are available to customers, upon request. O-rings are available in 7+ materials. We also offer an o-ring’s durometer on a scale of 50 (soft) to 80 (hard). Available durometer will vary for each o-ring material.

Ideal environment for o-rings and the cartridge seat varies depending on how the valve is being used. However, we customize components to optimize a valve’s performance for every customer’s unique

application requirements. Remember, no valve is completely leak free because of their physical properties, but we test 100% of all valves to ensure they seal.

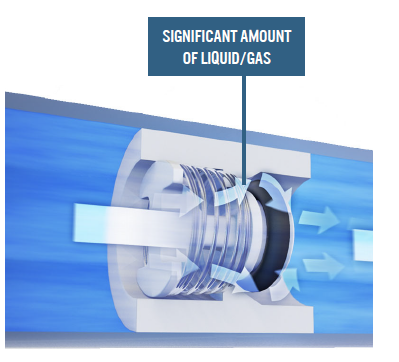

Stage 3: Open

Opening Pressure is Assigned

Stage 3: Open involves a significant chain reaction of events:

- Pressure builds

- The o-ring lifts off the cartridge seat

- A significant amount of liquid/gas flows through the valve

After this series of events, the valve’s opening pressure is assigned.

For customers looking for relief valves:

This stage is a critical step to understand because an accurate opening pressure ensures a device will function exactly to application requirements. Also note, customers can choose an opening pressure to suit their device’s requirements. Valves are rated at the pressure where the “open” stage occurs.

We use specialized equipment to measure the effects of pressure on a valve’s performance including the opening PSI assignment. During this test, pressure builds up within the test volume until the valve opens. The valve opens far enough to allow a large amount of flow to escape, which causes a sudden drop in pressure. The test equipment records the point of this occurrence. All Smart Products USA valves are rated in this manner.

Opening pressure ranges for Smart Products USA valves are 0.09 to 20 PSI.

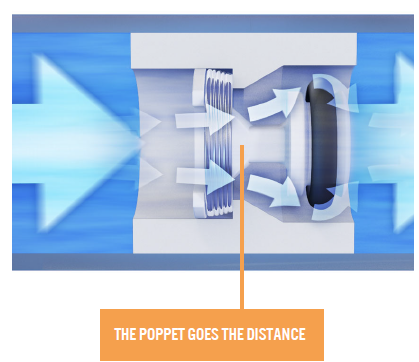

Stage 4: Fully Open

Regulated Pressure Occurs

During stage 4, the pressure moves fluid through the valve with such velocity that the poppet travels to its limit. At this point, the valve has achieved a FULLY OPEN state. Once the valve is fully open, more flow can still be achieved, but at a diminishing return because the poppet cannot travel any further.

For customers who want to maintain a level of pressure in applications, being aware of this stage is important. Once fully open is reached, a large pressure increase will be required to marginally raise the flow. That is why it is always good to make sure the valve you order has sufficient flow at your operating pressures. There are no operational penalties for a larger valve other than your space constraints.

Note: The minimum pressure (at which flow is possible) will surprisingly occur at a pressure lower than the initial opening pressure. This outcome happens because more pressure is required to overcome stiction, which can

occur if a valve is inactive and sits for a long period of time.

At Smart Products USA:

We have found that by applying a parylene coating to o-rings, they are able to remain idle longer without the risk of an elevated opening pressure. We test every series of our valves to establish performance in liquid and gas applications beginning with OPENING, progressing through OPEN or minimum regulated pressure (SSRP), and ending with RESEALING.

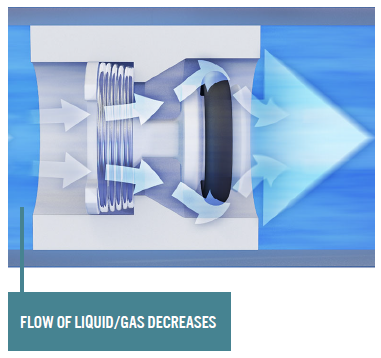

Stage 5: The Descent

Pressure Decreases

Stage 5: The Descent is when pressure in an application decreases, and the spring begins to pull the poppet back towards the shut or resealing position. Watching the process closely, the valve’s poppet begins to shut following a different path.

Note: the valve does not instantly return to the shut stage – a slight delay, hysteresis, occurs due to internal friction or a change in forces acting upon the valve. This lag does affect an application’s performance, but for most users it is so subtle that it is not even detectable. The journey back to resealing is not instantaneous. These factors make a valve have a difference in their opening pressure and reseal pressure. In fact, the reseal pressure is around 20% below the opening pressure.

The poppet plays a key role during these stages because it is the connection between the spring and o-ring seal. The poppet sets the spacing between these two components. Thus, it directly contributes to the actual pressure the valve operates at during all stages.

Stage 6: Touch Down

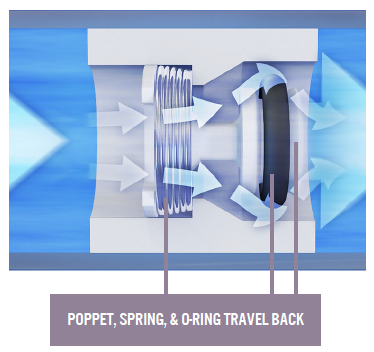

Internal Components Begin to Move Back

When the valve’s internal components (the poppet, spring, and o-ring) continue to travel, they eventually make contact with the o-ring seat, also known as Stage 6: Touch Down.

The valve will not seal well at this stage because there is no force pressing the o-ring back into the seat. As mentioned in Stage 2: Opening, o-rings appear perfectly smooth, but they can have tiny imperfections, and it is through these ridges and gaps that flow escapes. Therefore, the valve will not fully close until Stage 7: Resealing.

Stage 7: Resealing

Internal Components Back in Place

In Stage 7: Resealing, the o-ring continues its journey back to the seat. Previously, the o-ring was only touching the seat, but now the spring force (via the poppet) has compressed the o-ring enough to hold it into place and create a seal against every gap.

This stage is particularly noteworthy for customers with applications that cannot drop below a certain pressure because reseal pressure will always be lower than the opening PSI. For example, if your device requires a reseal pressure of 10 PSI, then you will want a valve with an opening pressure around 12 PSI. In addition, reseal pressures under 1 PSI may not be repeatable due to the low seat pressure.

At Smart Products USA:

The more we know about your specific pressure requirements, the more precise your check valve’s performance will be. To ensure accurate and reliable flow control, all of our spring-loaded valves have been extensively tested to determine their open, regulated, and reseal pressures.

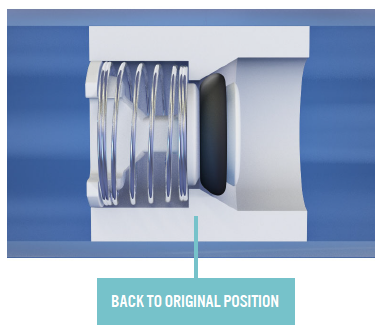

Stage 8: Reset

Valve is Ready to Repeat All Stages of Operation Again

Once the valve reseals, it is in Stage 8: Reset. The valve has returned to its original position and is ready to go through all eight stages of operation again.