About Our Series 100 Standard Pressure Valve

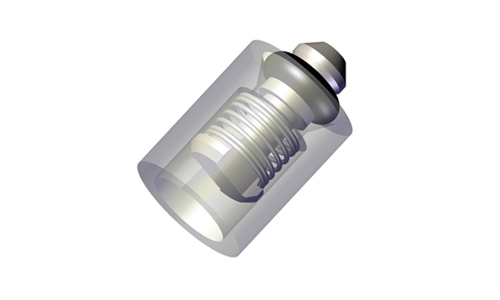

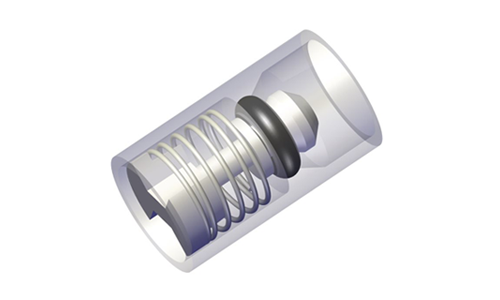

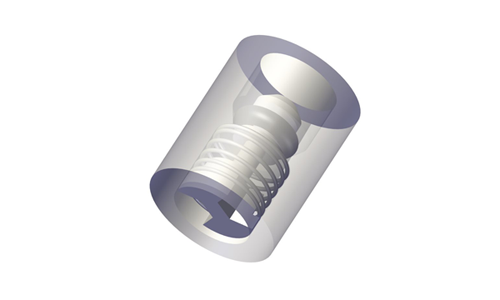

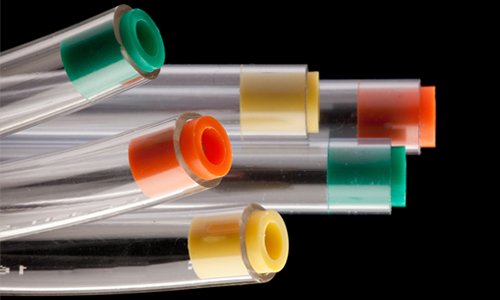

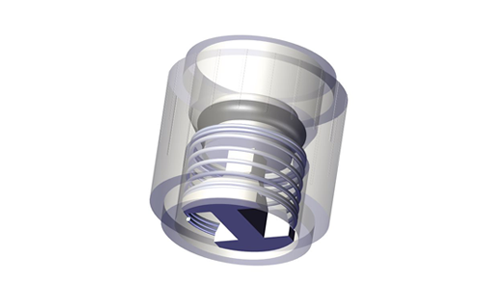

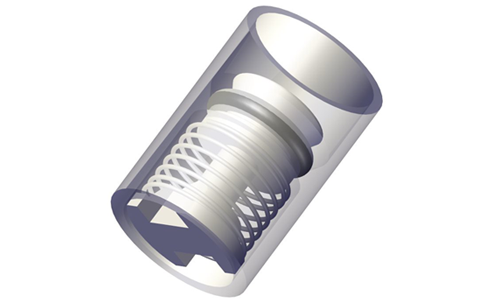

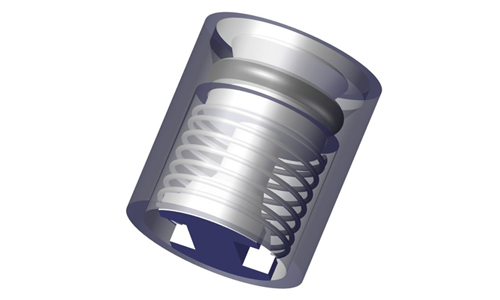

Used for liquid or air, our cartridge check valves can be incorporated into virtually any mounting style. They are easily inserted into fittings or manifolds, or can be installed in-line. Available in standard or manual relief bleed styles, Series 100 standard check valves and/or pressure relief valves range from 1/4” to 3/4” sizes and opening pressures from 0.09 to 20 PSI.

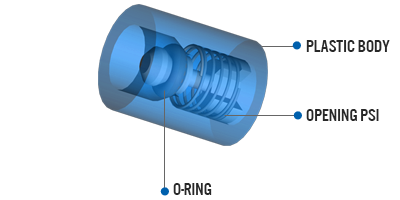

At Smart Products USA, all of our valves are also customizable! The custom options for standard pressure valves include:

- Plastic body material

- O-ring material

- Opening spring pressure to meet specific application criteria

Series 100 standard check valves also offer specialty styles in barbed, NPT, side seal, and flanged.

Contact Us

Drop us a line and we’ll get back to you quickly! Fill out the form or call 1-800-338-0404 for more information.

Model #110

Standard Cartridge: 1/4″

Size O.D.: 1/4″ (6.35mm)

Length: 0.500″ (12.70mm)

Body Materials: Polypropylene, Nylon, Acrylic, Acetal, PVDF, Polycarbonate, Ultem®, ABS

O-ring Options:

Buna-N, EPDM, Viton®, Silicone, Fluorosilicone

Spring Pressure: 0.09 – 20 PSI

Model #120

Standard Cartridge: 5/16″

Size O.D.: 5/16″ (7.94mm)

Length: 0.500″ (12.70mm)

Body Materials: Polypropylene, Nylon, Acrylic, Acetal, PVDF, Polycarbonate, Ultem®, ABS

O-ring Options: Buna-N, EPDM, Viton®, Silicone, Fluorosilicone

Spring Pressure: 0.09 – 20 PSI

Model #130

Standard Cartridge: 3/8″

Size O.D.: 3/8″ (9.53mm)

Length: 0.640″ (16.26mm)

Body Materials: Polypropylene, Nylon, Acrylic, Acetal, PVDF, Polycarbonate, Ultem®, ABS

O-ring Options:

Buna-N, EPDM, Viton®, Silicone

Spring Pressure: 0.17 – 20 PSI

Model #140

Standard Cartridge: 1/2″

Size O.D.: 1/2″ (12.70mm)

Length: 0.625″ (15.88mm)

Body Materials:

Polypropylene,

Nylon, Acetal, PVDF, ABS

O-ring Options: Buna-N, EPDM, Viton®, Silicone

Spring Pressure: 0.17 – 20 PSI

Model #150

Standard Cartridge: 5/8″

Size O.D.: 5/8″ (15.88mm)

Length: 0.630″ (16.00mm)

Body Materials: Polypropylene, Nylon, Acrylic, Acetal, PVDF, Polycarbonate, Ultem®, ABS, Radel®

O-ring Options: Buna-N, EPDM, Viton®, Silicone, Fluorosilicone, Aflas®, Kalrez®. (Note: Aflas® & Kalrez® are not available with springs less than 0.5 PSI)

Spring Pressure: 0.11 – 8 PSI

Model #157

Manual Relief Bleed Valve: 5/8″

Size O.D.: 5/8″ (15.88mm)

Length: 0.630″ (16.00mm)

Body Materials: Polypropylene, Nylon, Acrylic, Acetal, PVDF, Polycarbonate, Ultem®, ABS

O-ring Options: Buna-N, EPDM, Viton®, Silicone, Fluorosilicone, Aflas®, Kalrez®. (Note: Aflas® & Kalrez® are not available with springs less than 0.5 PSI)

Spring Pressure: 0.11 – 8 PSI

Model #160

Standard Cartridge: 5/8″

Size O.D.: 5/8″ (15.88mm)

Length: 0.630″ (16.00mm)

Body Materials: Polypropylene, Nylon, Acrylic, Acetal, PVDF, Polycarbonate, Ultem®, ABS

O-ring Options: Buna-N, EPDM, Viton®, Silicone

Spring Pressure: 0.17 – 20 PSI

Model #170

Standard Cartridge: 3/4″

Size O.D.: 3/4″ (19.05mm)

Length: 1.125″ (28.58mm)

Body Materials: Polypropylene, Nylon, Acrylic, Acetal, PVDF, ABS

O-ring Options: Buna-N, EPDM, Viton®, Silicone

Spring Pressure: 0.16 – 3 PSI

Model #174

Standard Cartridge: 3/4″

Size O.D.: 3/4″ (19.05mm)

Length: 0.835″ (21.21mm)

Body Materials: Polypropylene, Nylon, PVDF, ABS

O-ring Options: Buna-N, EPDM, Viton®, Silicone

Spring Pressure: 0.16 – 3 PSI

Why Smart Products Is Your Choice for Cartridge Check Valves

Along with being ISO 9001:2015 certified, one aspect that sets us apart from the competition is our dedication to producing high-quality, durable components that get the job done every time in every environment. Other reasons customers choose Smart Products include the following.

Our Ability to Customize an Order

We understand that every application is unique, which is why all of our products, including our standard check valves, can be configured to suit your application. From supplying diverse plastic body materials and O-ring materials to facilitating efficient spring pressure and valve design, we work closely with you to ensure your order meets your exact needs!

Every Valve Is Produced in the USA

We take pride in our manufacturing process, which is fully based in the USA. We ensure the highest quality control standards and the ability to quickly react to our customers’ needs for all of our products, including our standard pressure relief valves.

Note: Dimensions on this page are based on Polypropylene material. These are typically held to a +/- 0.005″ tolerance. Keep in mind different plastics have different shrink rates and may vary from these tolerances. Our products are subject to continuous improvement. To achieve this goal, Smart Products reserves the right to change features, processes, materials, testing and other specifications as necessary. All plastic body material recommendations are based on standard corrosion-resistant and compatibility guides.

Smart Products strongly recommends that customers test products for each application-specific use. Buyer is urged to test and investigate the compatibility of any substance used with our products prior to actual use. Seller will not be responsible for the failure of buyer to thoroughly test and investigate the compatibility of the substances used with our products and the fitness of the products for its particular use or application.