Understanding Stiction: Are your valves at risk?

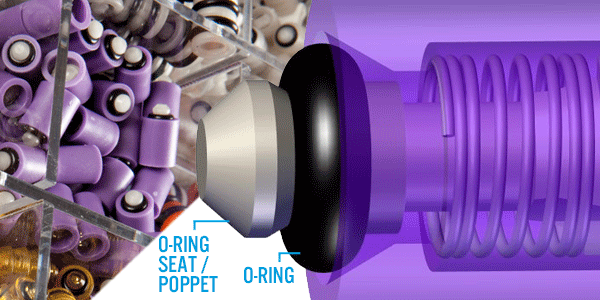

Stiction, defined as the friction that tends to prevent stationary surfaces from being set in motion, is a fact of life ruled by the laws of physics. Per our check valve operation guide, all valves begin in a passive state. They are not yet in contact with any liquids or gasses, but the valve’s components – plastic body material, o-rings, poppet, cartridge, and springs – remain in contact with each other. If a valve is inactive and sits for a long period of time, the o-ring can stick to the o-ring seat (poppet) and cause an elevated opening pressure. While stiction can’t be eliminated completely, we do offer a parylene coating for o-rings as a solution to combat against it.

With 9+ different plastic body materials, 7+ o-ring materials, and a wide variety of low opening spring pressures, it is virtually impossible to test all possible combinations of our valves, as well as anticipate all environmental conditions a valve will undergo. We do know that if a valve sits on a shelf for 30 days in a hot environment, it will most likely yield different results versus a valve that is going to be used right away. As a preventative method, it is a good idea to give us as much information about your application as possible on the front end to prevent stiction from being an issue and ensure your valve precisely works every time. For questions or more information, please:

|