Examining the Science of Rubber

for Optimal O-ring Seals

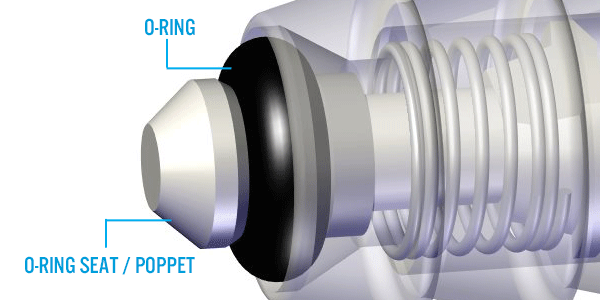

O-rings are a crucial component in our valves because they keep the poppet in place, as well as move forward off of the poppet’s cartridge seat to allow regulated flow through the valve. At first glance, o-rings can be described as circular rings of rubber used as seals for our check valves. However, when viewed at a structural level, they are a lot more complex. Their chemical makeup can be altered in a variety of ways to meet application-specific needs. This eBlast touches on the scientific aspects for three of our o-ring material options: Buna-N and EPDM, both copolymers, and Viton®, a fluorocarbon.

With o-rings, there really are seemingly endless possibilities, especially when viewed at a scientific level. In our experience, we have encountered customers who have stated a particular o-ring material did not work in their application, but upon further examination a different variation of the same rubber did work. For Buna-N, aka Nitrile, it is known by the chemical name acrylonitrile butadiene copolymer. A key component of this rubber is that the acrylonitrile content of nitrile sealing compounds varies considerably (from 18% to 50%), and this difference influences the physical properties of the finished material.

EPDM, another copolymer, is known by the chemical name ethylene-propylene diene rubber. Like Buna-N, its properties can be manipulated to change certain characteristics of the o-ring, such as the ethylene and diene contents.

For Viton®, aka Fluorocarbon or FKM, it is known as an organic compound made up of carbon and fluorine. In addition to standard FKM materials, a number of special materials are available with differing monomer compositions and fluorine content. These variations result in improved low temperature, high temperature, or chemical resistance performance.

Pictured below left to right: are Buna-N orings, typically black in color and inserted into an Acrylic Model #150, Polycarbonate Model #502/502, and Green Polypropylene Model #132. EPDM o-rings, typically purple in color and inserted into a PVDF Model #120, Radel® Model #304/304, Polycarbonate Model #152, and Purple Polypropylene Model #110. Viton® o-rings, typically brown in color and inserted into Polycarbonate Model #500/500, Nylon Model #122, Ultem® Model #111, and PVDF Model #154.

|

|

In addition to the unique chemical makeup of o-rings, they can also be altered by viscosity, durometer, compression, curing options, and more. At Smart Products, we offer o-rings in Buna-N, EPDM, Viton®, Silicone, Fluorosilicone, Aflas, and Kalrez®. However, when examining the physical properties of o-rings, we actually offer a lot more options versus the seven materials listed above. The nature of o-rings allows new and varied compound combinations to continuously enter the marketplace, which brings lots of options to the o-ring varieties we offer.

Over the years, we have worked with hundreds of thousands of different chemical compounds, temperature requirements, and maximum amount of exposure in both elements. Thus, we can recommend the ideal o-ring for your specific application environment based on the information you give us. If you test a lot of compounds and know what works in your system, share it with us so we can ensure every component of our valves will work for your application requirements.

To review, the o-ring is one component of our valves that we can flexibly work with to ensure maximum performance for the most straightforward or complex systems. Combined with plastic body material and opening spring pressures, we have millions of possibilities to create the right valve for you.

For questions or to start creating your ideal low pressure, low flow valve solutions, please: contact us.

|