D2P Grapevine

Grapevine, TX

March 14 & 15

Gaylord Texan Conv. Center

Booth #227

More Info

D2P Atlanta

Atlanta, GA

March 28 & 29

Cobb Galleria Centre

Booth #126

More Info

|

|

|

How to select valves for pneumatic devices

|

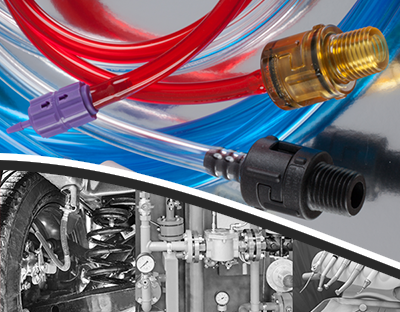

Working with compressed air or gasses? Smart Products USA has over 30 years of experience building customized check / pressure relief valves for a wide variety of pneumatic systems. Example applications include: brake systems, solar-powered air compressors, gas analyzers and equipment, dental and medical equipment, paint sprayers, and much more.

To begin building your own custom valve, first view our many check / pressure relief size and style options. Next, customers work closely with a Product & Application Specialist to determine the right plastic body, o-ring, and opening PSI combination. For plastics, Polypropylene is our go-to option, but we also see a lot of requests for specialty plastics, such as Nylon, which works well for air/gas applications that require a slightly higher heat resistance. We also offer Ultem® to meet even higher temperature requirements. Additionally, we have several o-ring options to include Buna-N, EPDM, Viton®, and more. We offer technical assistance selecting these components, as well as opening psi requirements, flow rates, and more.

As always, it is important to discuss all liquids / gasses coming into contact with our valves, application environment, and intended shelf-life with us. For questions or assistance with your own unique low pressure, low flow project, contact us at (800) 338-0404 or sales@smartproducts.com.

To view a PDF of our entire product catalog, click here.

Series 100 Flanged Valves

Primarily used for pressure relief, our flanged valves allow customers to easily insert them into a variety of devices ranging from battery packs to tanks. This family of valves includes the following:

For extra protection against leaks, the Model #154, and its reverse flow option, Model #191, are both great options due to their external side seal o-rings. Model #14c is tapered at the end, which means it is molded into a more angular flange allowing for lower visibility within an application.

For more information about our flanged valves or to discuss your project needs with a Product & Application Specialist, contact us at (800) 338-0404 or sales@smartproducts.com.

|

|

|