How does the sense of smell affect humans? Researchers striving to answer this question have a need to obtain a precise control over odor presentation – and using an olfactometer is a must. However, many find these instruments too pricey for their budgets – until researchers at the Monell Chemical Senses Center recently published “Methods for building an inexpensive computer-controlled olfactometer for temporally-precise experiments“ in the International Journal of Psychophysiology.

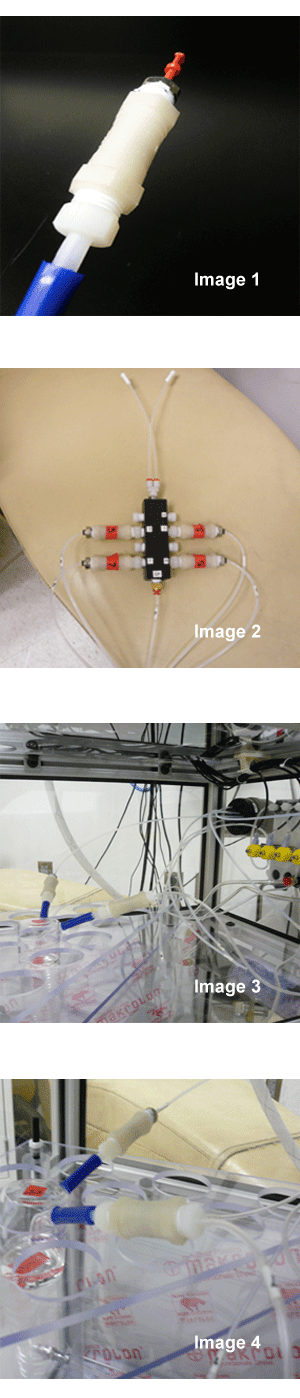

Smart Products’ Series 200 NPT Check Valves/Pressure Relief Valves play an important role in this equipment by controlling the flow of air in two key places: the inlet and outlet of the odorant reservoir (Images #1, #3, #4) and at each inlet leading to the nasal manifold (Image #2).

“We used Smart Products’ check valves, as opposed to those made by another manufacturer, because of their low actuating pressure of 0.07 to 0.11 PSI, and the fact that they are small and nearly silent when actuating. I cannot tell you how many different check valves I tried before finding Smart Products,” says Researcher Amy Gordon of the Monell Chemical Senses Center.

As described in the publication, the olfactometer has the ability to present temporally-precise odor stimuli originating from a large variety of solid or liquid odor sources in an automated fashion. The images to the right display the use of Model #204 at the inlet and outlet of the glass odorant jars, and the use of the same check valve at each inlet of the nasal manifold. There is another type of odorant reservoir that can be used with this olfactometer model, which uses Model #214/214 at the inlet and outlet of each reservoir.

Flow Control at the Odorant Reservoir

At the odorant reservoir inlet, these check valves prevent odorized air from leaking out and contaminating upstream tubing, fittings, and other valves. They also help maintain pressure in each line of the olfactometer, which means that as soon as an upstream solenoid valve is actuated and allows air through, the pressurized line ahead already contains air ready to be pushed forward to the subject's nose. For the reservoir’s outlet, another valve is used to prevent odorized air from continually flowing from the reservoir towards the subject's nose.

Flow Control at the Nasal Manifold

Additional valves are used at the nasal manifold to ensure a subject experiences a quick onset and quick offset of an odor stimulus, rather than a gradual baseline of weak odor that occasionally increases and decreases. Thus, the same goal is also achieved at this section of the device – maintaining pressure in each line and preventing continuous flow to the subject’s nose and down other odorant lines.

Without these check valves in place, a weak flow of odorized air from different odor reservoirs would make its way down the lines to the subject, mix in the nasal manifold, and flow upstream down other odorant lines.

Gordon adds, “With Smart Products check valves in place at these two points, odorized air is pushed from an individual reservoir and to a subject's nose only when an upstream solenoid valve opens; an open solenoid valve allows air flow through that individual channel, increasing pressure there and overcoming the opening pressure of the check valves only in that particular channel. This allows odorized air from the experimenter-specified channel to flow directly to a subject – and allows that to happen quickly.”

“Over the past few years, we have built many models of this olfactometer – each an update of a previous version – and in each model we've used different types of odorant reservoirs. In every single model and for every type of odorant reservoir, we've used Smart Products check valves in Polypropylene with Buna-N o-rings and the lowest opening pressure available. For the model described in our recent publication, we used Series 200 valves, but in our newest model we’ve switched over to a mixture of Series 300 and Series 200 valves.”

The creation and ongoing development of this equipment will allow other olfactory researchers to build similar devices for their own experiments.